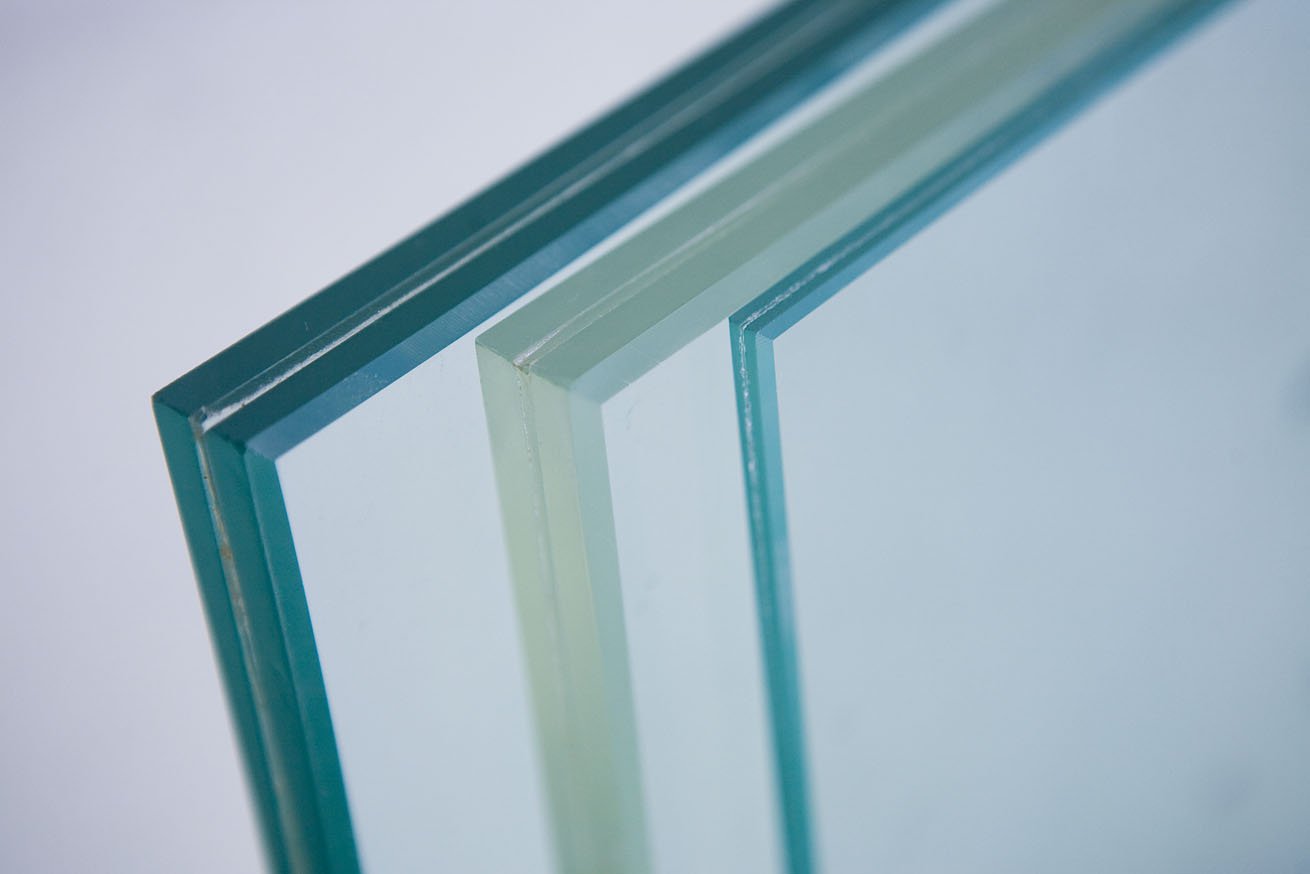

Toughened/Tempered Glass

Toughened or Tempered Glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared to normal/float glass. Glass is usually heated based on its thickness to a point where it nearly softens and is then rapidly cooled. Tempering causes the glass to break in granular chunks as compared to shards in annealed glass, making toughened glass absolutely safe. Tempered glass has a variety of applications such as passenger vehicle windows, components of bullet resistant glass, shower cubicles,buildings and structures, floors, roofs,railings etc. No physical changes such as cutting, grinding, drilling can be made once the glass is toughened. Toughened glass is four to five times stronger than annealed glass and two to three times stronger than heat strengthened glass. It can withstand temperature differences between -2 degrees C TO 300 degrees C. For glass to be considered toughened, the compressive strength on the surface should be 69 MPa or (10,000 psi), for it to be considered safety glass the compressive strength should exceed 100 MPa(15,000 psi).